The Challenge: Complex CAD Tools and Fragmented Workflows

For many makers, small businesses, or hobbyists, traditional CAD and 3D printing workflows feel daunting. Heavy, desktop-installed software is often expensive, hard to learn, and creating printable models typically involves multiple tools: modeling software → export → slicer → printer. On top of that, using a home 3D printer often means compromises on print quality, surface smoothness, and reliability.

That friction has limited what many people — designers, entrepreneurs, educators — can build.

The Womp Advantage: Browser-based Modeling + Integrated Professional Printing

Womp removes those barriers by combining intuitive, browser-based 3D modeling with professional-grade custom printing services — all in one place.

- No downloads or installations needed — just open Womp in your browser and start designing.

- Export clean, print-ready files (STL, OBJ, GLB) with watertight meshes and minimal geometry errors — ideal for both desktop printers and professional print services.

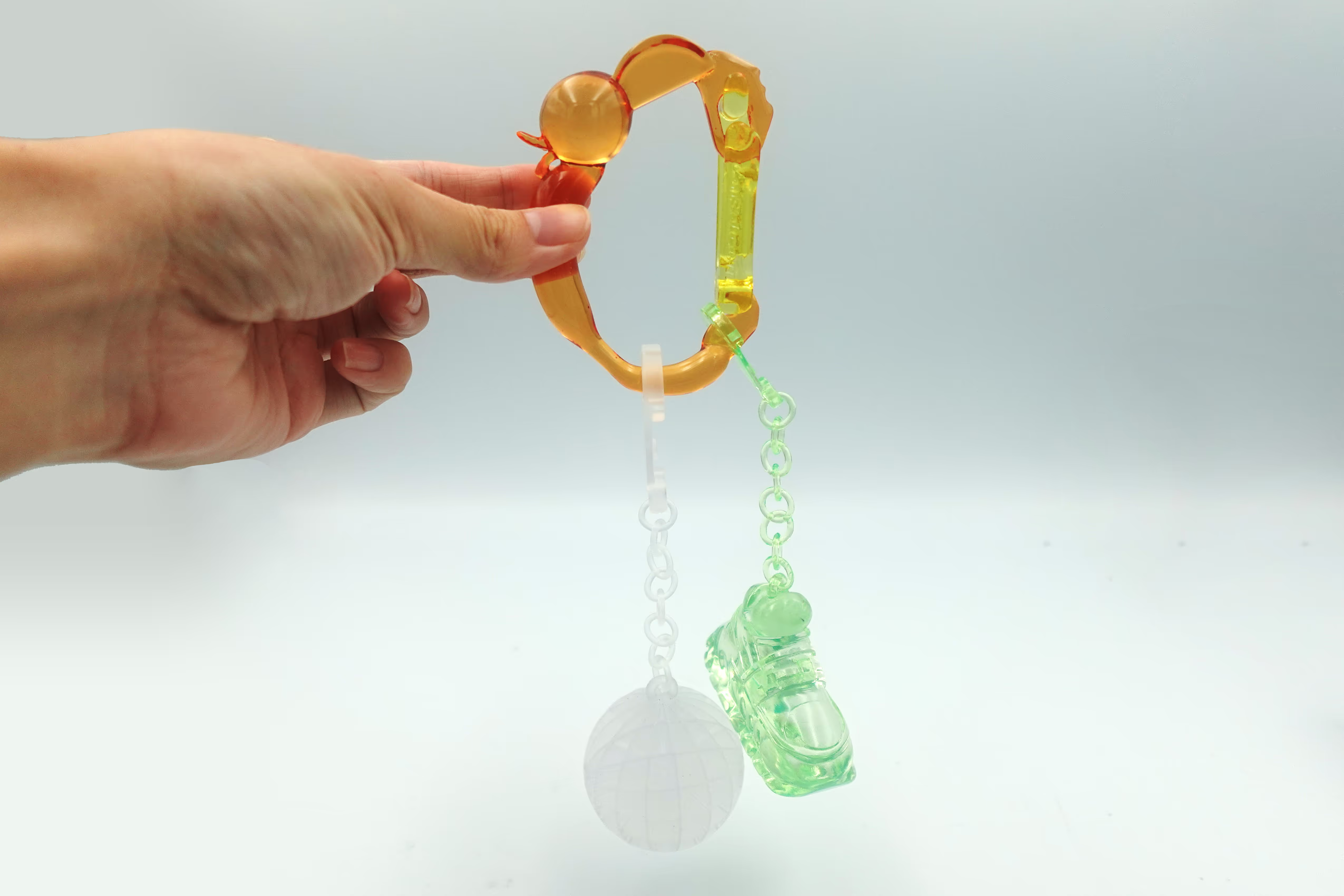

- Access to high-quality materials and SLA printing: With options like Womp’s White Prototyping Plastic (WPP) or clear resin, prints come out with smooth surfaces and reliable quality — far beyond what typical hobbyist printers deliver.

- Streamlined workflow — from idea to physical object: Design → optimize → order print → receive physical product. No file-handoffs, no manual slicing, no guesswork.

Fair, Transparent Pricing: Pay for Volume, Not Parts

A frequent pain point with many 3D print services is per-part pricing. That approach penalizes users who upload multiple small, unconnected parts — even if they all fit in one print run. Womp’s volume-based pricing changes the game.

- Cost based on actual resin/volume used (including support material, internal cavities, orientation) — not the number of parts.

- More predictable, transparent pricing, ideal for budget-conscious creators, small businesses, and batch orders.

- Encourages optimized design: Hollowing, combining small parts, minimizing supports — good design habits that also save you money.

This pricing model aligns with how actual SLA printing works — making sure you pay for material and machine usage, not arbitrary part counts — and thus builds trust and clarity for users ordering prototypes or small batch runs.

From Prototype to Product — Why 3D Printing Matters Now More Than Ever

3D printing (additive manufacturing) has matured significantly — and its value extends beyond hobbyist projects. As noted by manufacturing and engineering experts, 3D printing enables rapid prototyping, complex geometries, customization, and shorter development cycles — advantages especially compelling for engineers, startups, product developers, and creative professionals.

Using Womp, you can tap into those benefits without needing expensive equipment or deep technical expertise. Rapid turnaround, integrated materials, and print-ready output — all make it easier to go from concept to physical object in days instead of weeks.

Who Should Use Womp — And What It Enables

- Startup founders and product designers who want to prototype ideas quickly and affordably.

- Small businesses and entrepreneurs needing short-run production, custom parts, or limited-edition products without mass-manufacturing overhead.

- Educators and students exploring 3D design and fabrication without complex tools or heavy setup.

- Artists, hobbyists, makers, and creatives who want professional-looking prints without managing their own printers.

- Engineers and professionals needing precise parts, functional prototypes, or custom tools and fixtures.

How to Get Started — Best Practices for Success

- Design efficiently — use hollowing, minimize unnecessary supports, optimize wall thickness to reduce material costs. This helps you leverage volume-based pricing wisely.

- Plan for the end use — choose materials accordingly: WPP for prototypes or functional pieces, clear resin for display items or transparent designs.

- Iterate quickly — use Womp’s browser-based modeling to rapidly test variations, then order prints to validate designs physically.

- Bundle parts when possible — if you have multiple small components (e.g. parts for a mechanical assembly), grouping them in one print reduces cost and saves time.

- Use 3D printing strategically — for prototyping, short-run manufacturing, bespoke designs, or custom tooling — not necessarily for large-volume mass production where traditional manufacturing may still be more cost-effective. This balances strengths and limitations of additive manufacturing.

Conclusion: Womp is Where Ideas Become Reality

Womp bridges the gap between creative ambition and manufacturable reality. By providing a seamless, accessible, and cost-effective path from browser-based 3D design to professional-quality physical prints — complete with transparent pricing and high-quality materials — Womp empowers creators of all kinds.

Whether you’re a hobbyist wanting to bring your concept to life, a startup building prototypes, or an educator teaching design and fabrication — Womp removes traditional barriers and brings 3D printing within reach.

Ready to unlock the potential of 3D printing? Visit the Womp 3D Printing page to get started today.